Negative Number: 22290

Latitude: 39.0

Longitude: 77.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): South Atlantic States: Dist. of Columbia

Card Front:

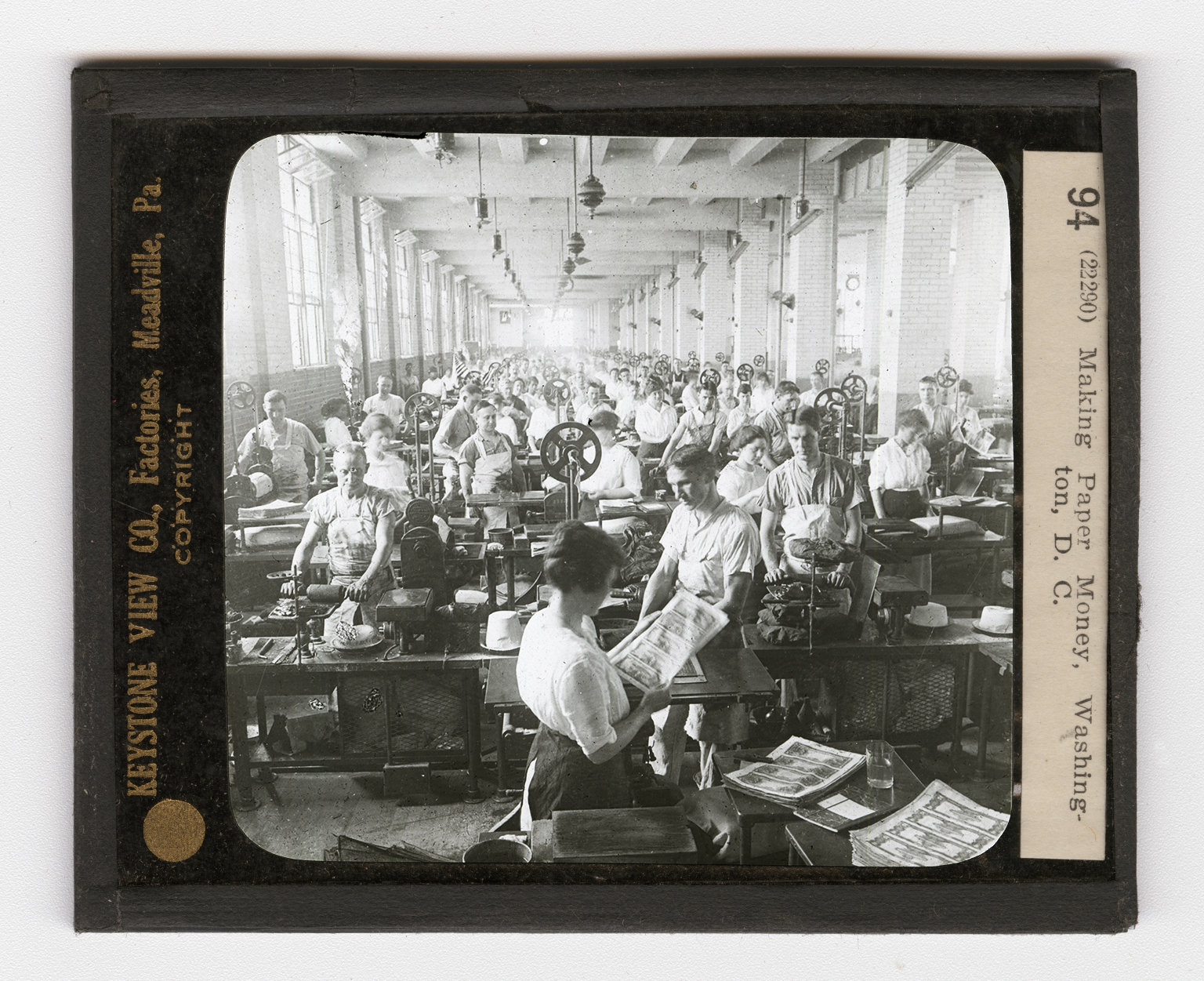

The making of paper money is under the control of the Treasury Department. Here you see the printing of bills in the bureau of printing and engraving. There is nothing unusual about this printing, but a great deal of care must be taken to see that the proper plates are used, in every case. Each bill is a part of a series and is marked with its proper letter and number. The most interesting process in making paper money is in the making of the paper. At Dalton, Massachusetts, there is a so-called "Government Mill", owned by the Crane family, which makes 99% of the paper used in our greenbacks. This mill is a three-story brick building of simple construction, but inside it is a process of paper making that is not generally known. Each piece of paper money contains two lines of silk fiber. The process of inserting this silk fiber is called the Crane process. You would not be allowed to

Card Back:

see how these fibers are inserted if your permitted to visit the mill. Any one who might be fortunate enough to re-discover the process, would not be allowed to make this kind of paper. If he does, he is subject to a fine of $5,000 and 15 years in prison. The paper is sent to the Treasury Department in packages of 1,000 sheets. The printing of the bills is done from plates on hand presses. Each pressman is given one package of note paper, enough to make 4,000 bills. With the aid of one woman helper, he prints 2,000 bills a day, on one side only. At the end of the day all stock is carefully checked before the workmen can leave. This is to prevent stealing. In the printing department of the Treasury, over 600 people are employed. What makes paper money valuable?