Negative Number: 7090

Latitude: 40.0

Longitude: 75.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): Middle Atlantic States: Pennsylvania

Card Front:

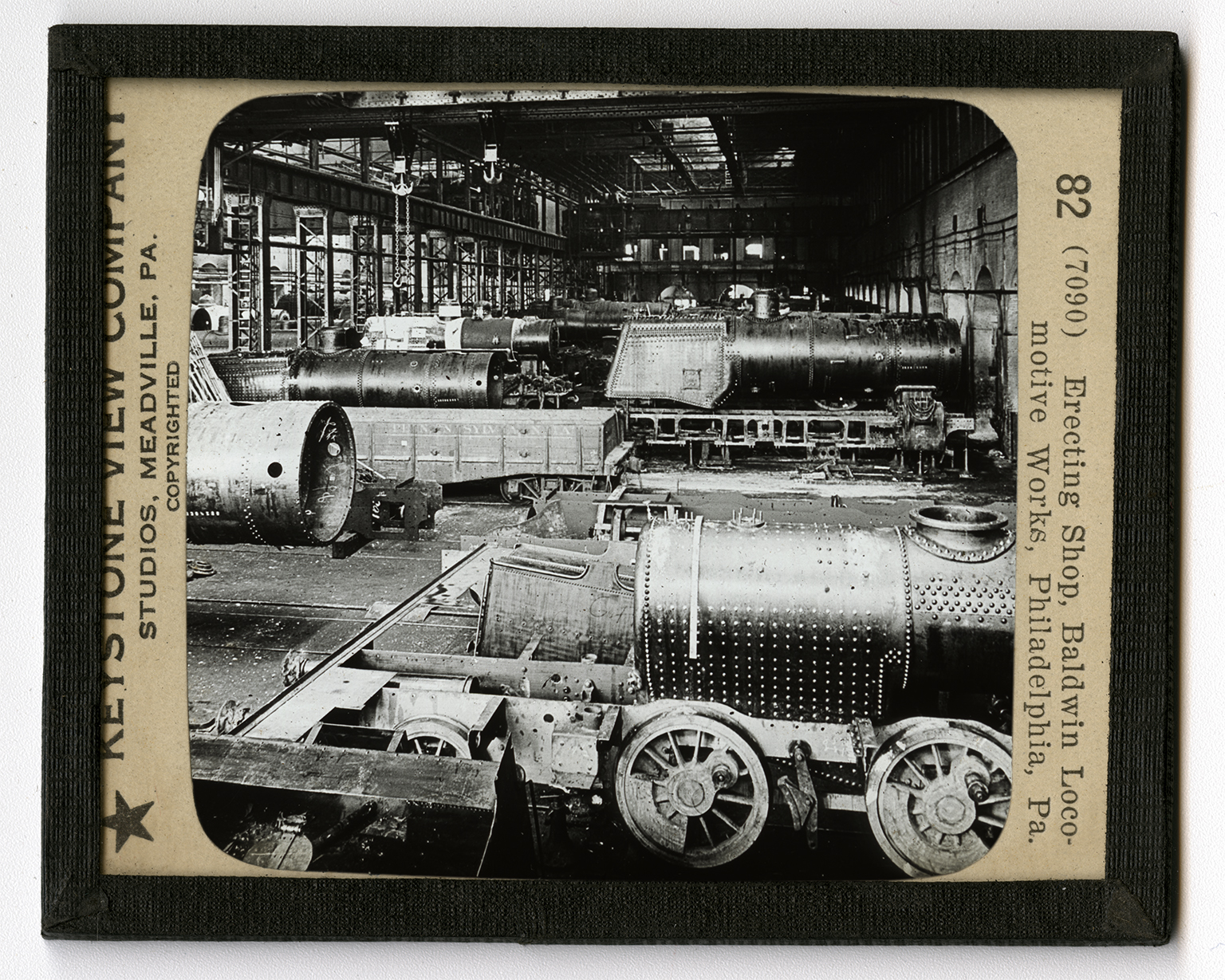

In the Baldwin Locomotive Works are built some of our greatest engines, noted for their speed, their power, and their size. In no other country in the world do you see such large or such powerful locomotives as are regularly used on our railroads. This section of the plant is called the erecting shop. It might also be called the assembling room. You will note that the great room is divided into two sections by an open framework of steel on the left of the view. On this framework rests one end of the large traveling crane that you see at the top of the view. The crane moves by its own power from one end of the shop to the other. The lifting of all the heavy parts is done with this device. One of these cranes can readily pick up and move an engine weighing 100 tons. Locomotives are built in the same general man-

Card Back:

ner as most of our other machines. Wheels of a certain kind are cast in one section. Wheels of another kind are cast in another section. Boilers are forged in another part of the territory, and so on. The various parts of a particular kind of engine are sent to this erecting shop where they are put together, and the engine is set up on the tracks. There are 19 tracks on this assembling floor, and most of them can handle 4 locomotives at one time. Eight of these monsters are run out of the shop, finished each day. In the Baldwin Locomotive Works the biggest engine in the world was constructed. This is the Triplex Compound, built for the Erie Railroad. It is 105 feet long and weighs over 476 tons. It can pull a freight train 5 miles long, weighing 54,000 tons.