Negative Number: 6414

Latitude: 40.0

Longitude: 80.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): Middle Atlantic States: Pennsylvania

Card Front:

Steel is refined iron. You will recall that in making iron heat is the principal factor. The crude iron ore is heated and refined to a certain degree, and then is fashioned into various forms. There remains a great deal of phosphorous and sulphur. These elements make it brittle. Iron is changed into steel by further heating which burns out the phosphorous and sulphur, and injects carbon into it. It is easy to take a piece of iron and transform it into steel by a very simple method. That is the old method of putting cast iron into a vat and heating it until it melts. While is white-hot it is stirred very rapidly. This stirring allows the heat to enter every part of the metal and burn out the impurities. The metal is then known as wrought-iron. If this is packed with carbon for several days and still kept white-hot it will come to be the

Card Back:

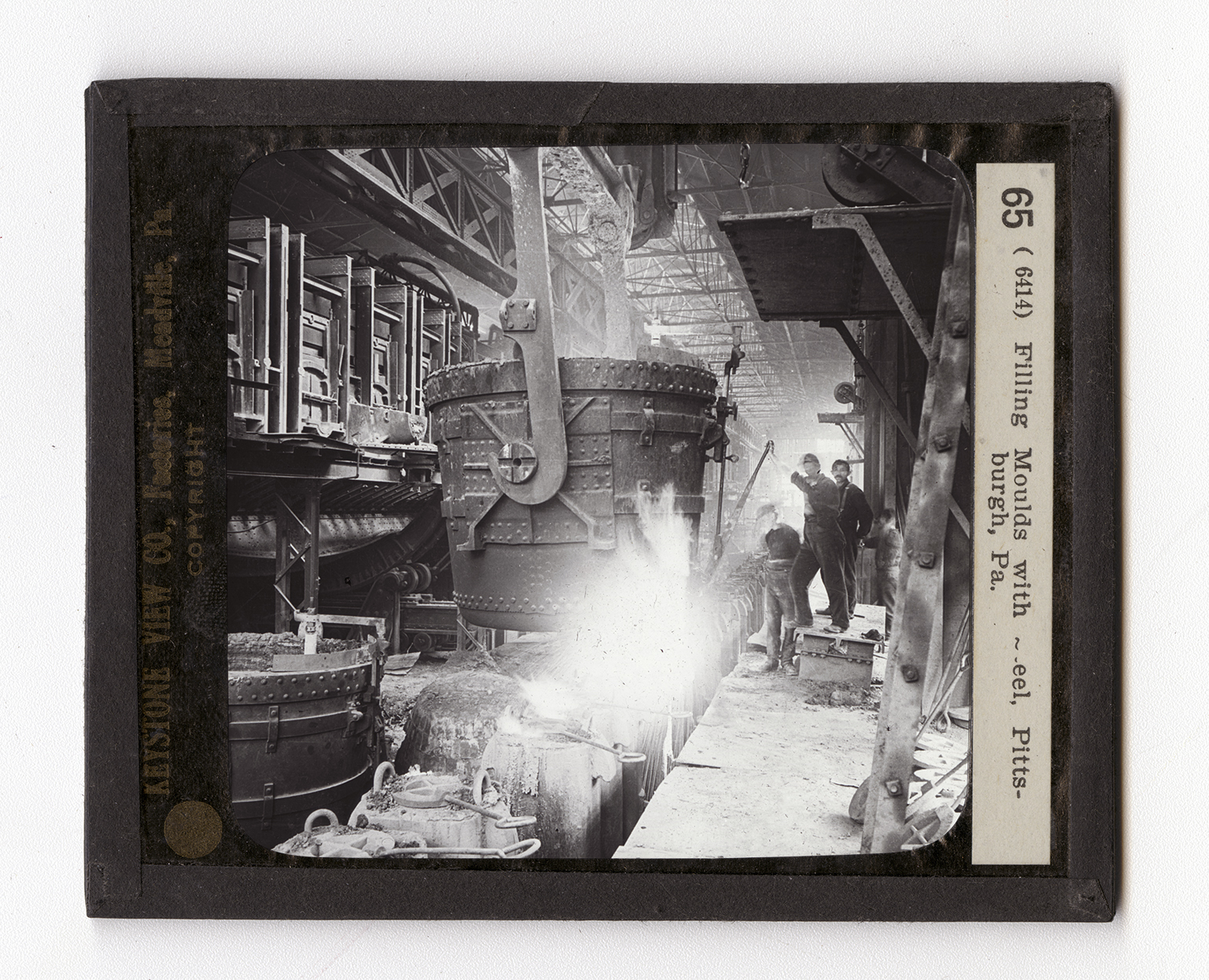

finest quality of steel. We still make steel in this way -- the steel that is used in fine carpenters' squares and in fine cutlery, such as carving knives and razors. This method of making steel is very slow. Bessemer invented a process of injecting carbon into the molten metal while it is white-hot. This is done in great blast furnaces. You see here what happens to this carbonized metal just after it is drawn out of the furnaces, which are to the extreme left of the view. The big steel pail, lifted by a crane, is full of hot metal. It moves above a row of molds, each of which is filled from the pail by pulling a lever. One of these molds is receiving the red-hot metal. The molds (they look like barrels) this side of the pail are filled with the cooling steel covered with sand. The blocks of steel in these molds are called ingots.