Negative Number: 6523

Latitude: 40.0

Longitude: 80.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): Middle Atlantic States: Pennsylvania

Card Front:

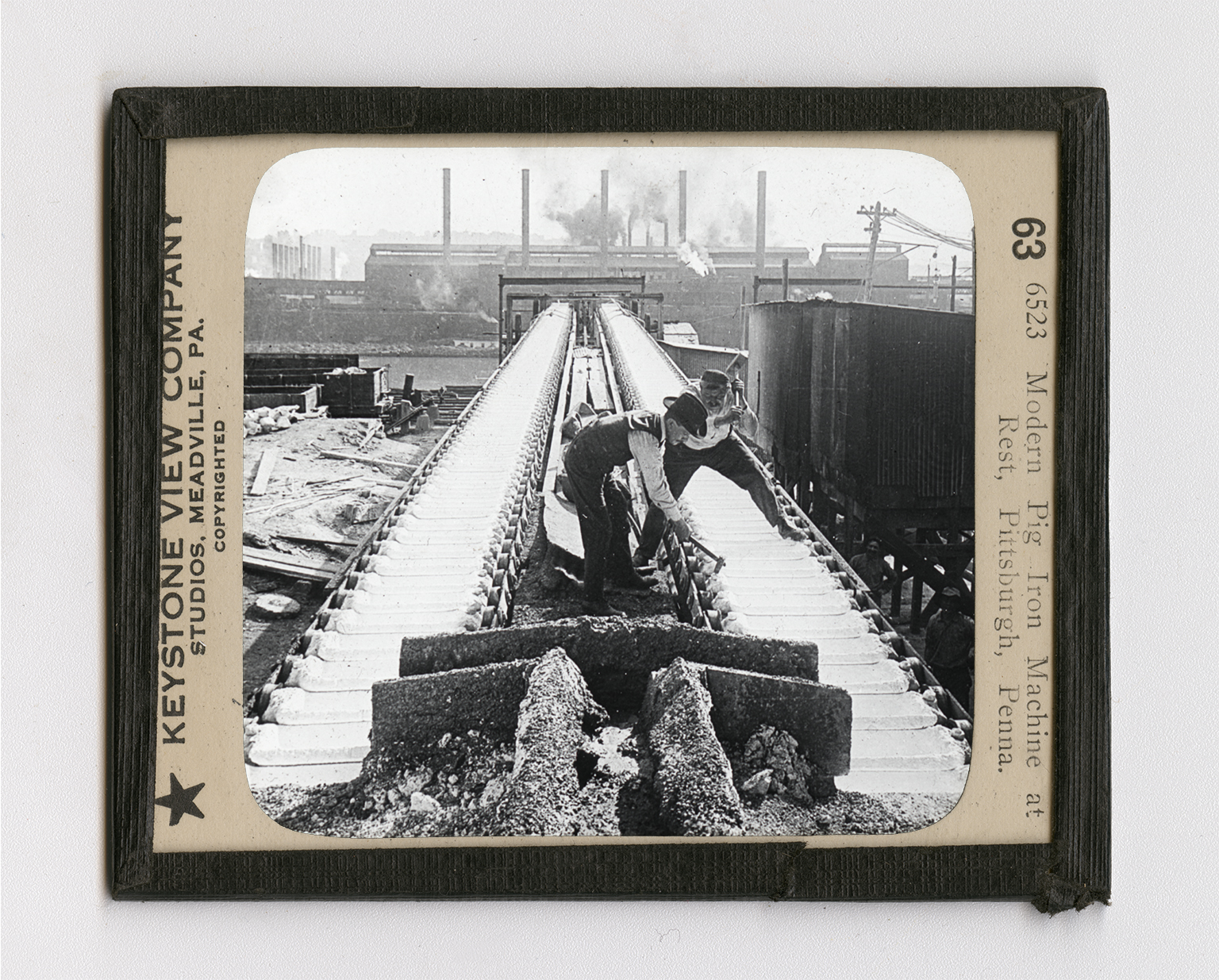

You see here the finishing operation in the making of pig iron by the latest method. In the old-fashioned method of making pig iron, the molten metal ran from the blast furnace into a long channel of sand. From this channel smaller channels, called sows, branched. From the sows, little channels, called pigs, extended. Men with poles punched the molten iron to make it flow evenly into the pigs. When the metal had cooled under sand, it was broken loose from the pigs in the form of pig iron. Then it was ready for shipment to the steel refinery. The method here shown is much quicker in operation and saves a great deal of labor. Here you see two revolving belts made of cast iron molds. Each mold is coated with lime so the hot iron will not cling to its surface. The belts rotate slowly. Directly in the foreground of the view is the trough down which

Card Back:

the red-hot iron flows. It pours from each side of the trough into then molds, so that each little trough is properly filled. At the farther end of the belts are the railroad switches. A freight car stands ready to receive the pig iron, which has cooled by the time it has traveled that distance. As the chain of molds revolves around the spool above the freight car the blocks of iron fall out of the molds into car because of their weight. By this process, practically, all of the handling of the metal is done by machinery. The large trough in the foreground is filled by ladles, each of which holds fifteen toons of molten metal. These ladles, in turn, are filled directly from the blast furnaces. The river you see beyond the railroad track is the Monongahela.