Negative Number: 10047

Latitude: 15.0

Longitude: 121.0

Geographical Classification:

Asia: East Indies: Philippines

Card Front:

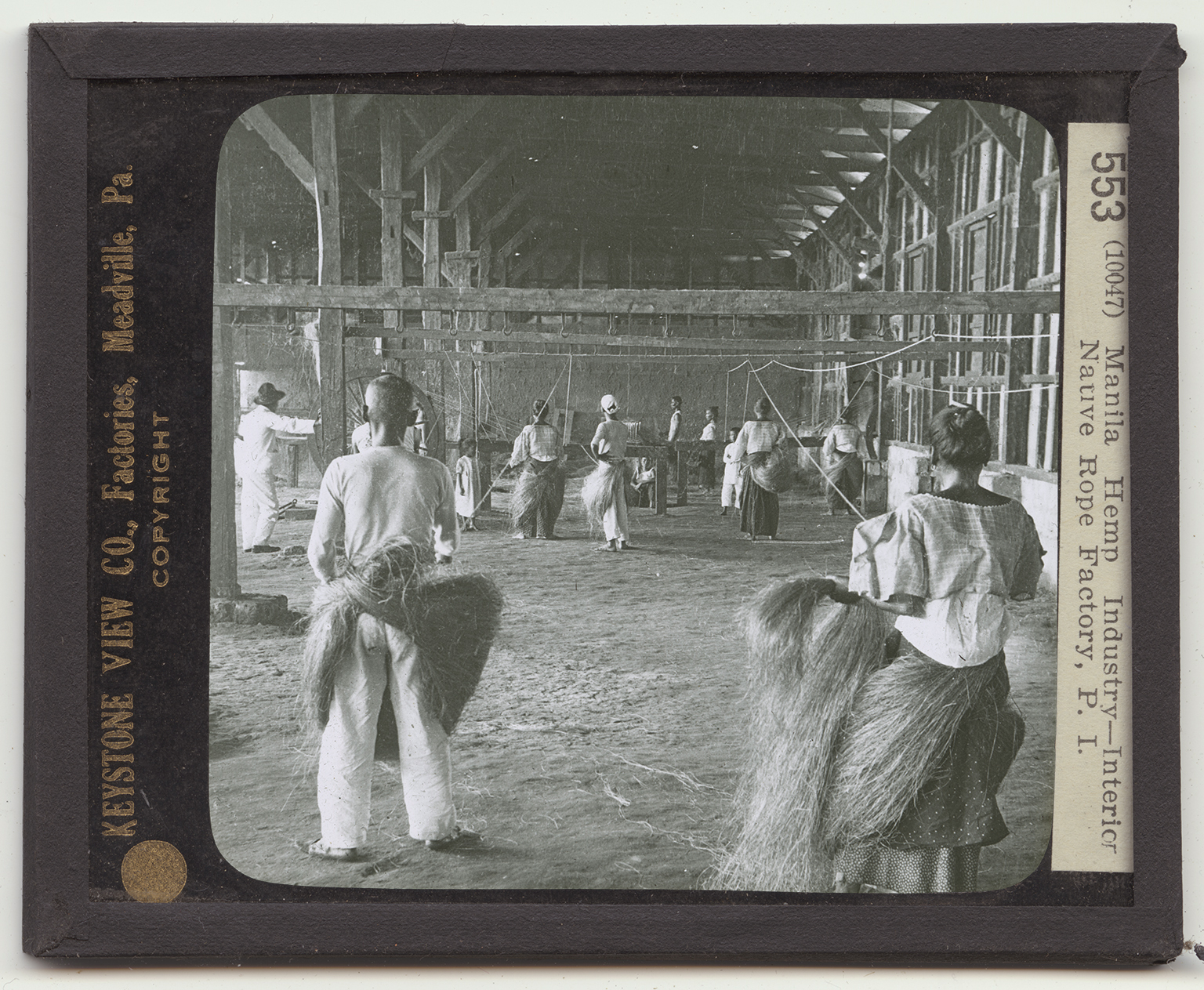

This shed is called a ropewalk. Here ropes are made from Manila hemp. This factory is in the Philippines. Making ropes by hand is a past art of the United States. Our ropes here are made by machinery. But in the Philippines hand labor is cheap, and machines are not so much used. After the abaca is dried, the fibers are known as Manila hemp. The fibers are then hackled. That is, they are drawn through spikes to straighten them, and to remove the remaining pulp from them. A fair per cent of this hemp is made into ropes. The method you see used here is simple, and is suggested by the name of the building. The object is to twist the fibers into long strands, and in turn to twist strands together. To do this the workmen have to walk back and fourth many times across the shed. About their waists the workmen carry bunches of fiber. One end of a small roll of fibers is

Card Back:

fastened to a spindle. This spindle is turned rapidly, twisting the fibers together tightly . As the rope twists, the workman walks, feeding out fiber from his waist. The size of the rope depends on the number of fibers started on the spindle. The lenght is determined by the market demands. Any lenght desired can be made by splicing sections of the rope, or by taking small ropes and twisting them together in the same fashion as the smaller ropes are made. In our New England states, about the time of the Revolutionary War, there were many such ropewalks as this one. Then New England was one of the chief ship-building sections of the world. The vessels were sailing craft, and a great deal of rope was needed to handle the large amount of canvas each ship carried.