Negative Number: 22111

Latitude: 41.0

Longitude: 74.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): Middle Atlantic States: New Jersey

Card Front:

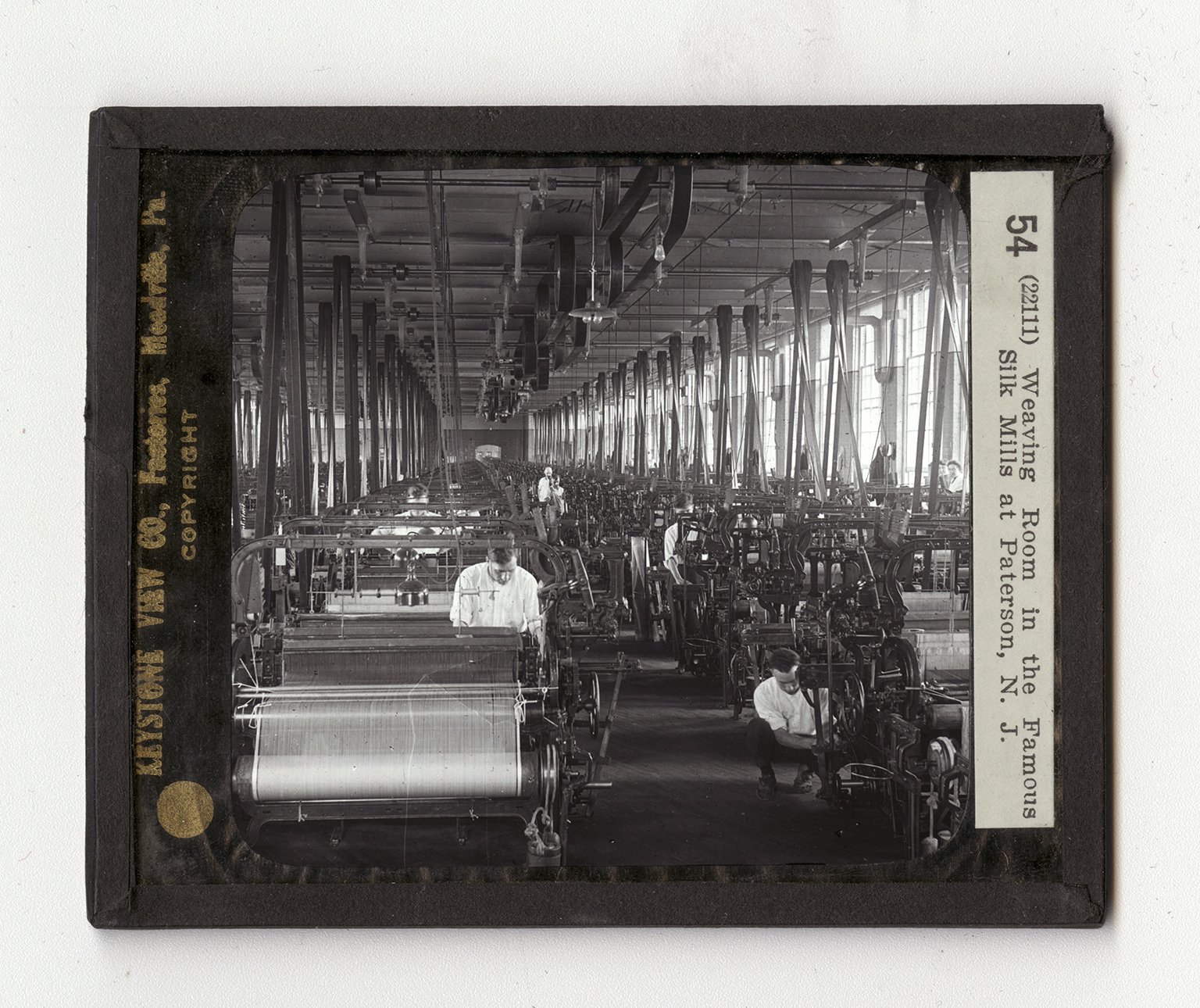

After silken threads from the cocoons are spun into yarn, they may be dyed or used plain. The next big process in silk manufacture is the weaving. The threads are first drawn from the spools of yarn to make the warp. The warp is the body of threads that run lengthwise in a piece of cloth. The yarn is drawn on large reels so the threads lie singly side by side in straight rows. These threads may be 1500 feet in length. The warp is as wide as the piece of cloth is to be made. The threads are drawn from the reel on a beam. This beam will afterwards be placed in the loom. The threads are then "harnessed" so each will have its own little path through eyelets. If a thread becomes tangled or is broken, the weaving stops. This is the reason that such care is taken in preparing the warp. Finally the beam and the harnessings are set into the looms.

Card Back:

Weaving any kind of cloth consists in intercrossing two sets of thread. The threads in the warp run lengthwise. The crosswire threads are shot under, over, and through the warp by shuttles. These threads are called the woof or weft. The yarn in silk woof is generally loosely woven. It is wound upon a quill, and the quill fits inside a shuttle. As the shuttle goes back and forth, the yarn unwinds as fast as it is needed. The view shows a great battery of looms thundering away. The clattering of the thousands of shuttles sounds like the noise of a battle with rifles. To and fro fly the shuttles as the threads of the warp are lifted. Up flashes the reeds to push the woof tightly against the warp. The machines that do this appear to be human. But sometimes a thread breaks, and the shuttles must be filled. The workmen must be on the lookout.