Negative Number: 22164

Latitude: 41.0

Longitude: 74.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): Middle Atlantic States: New York

Card Front:

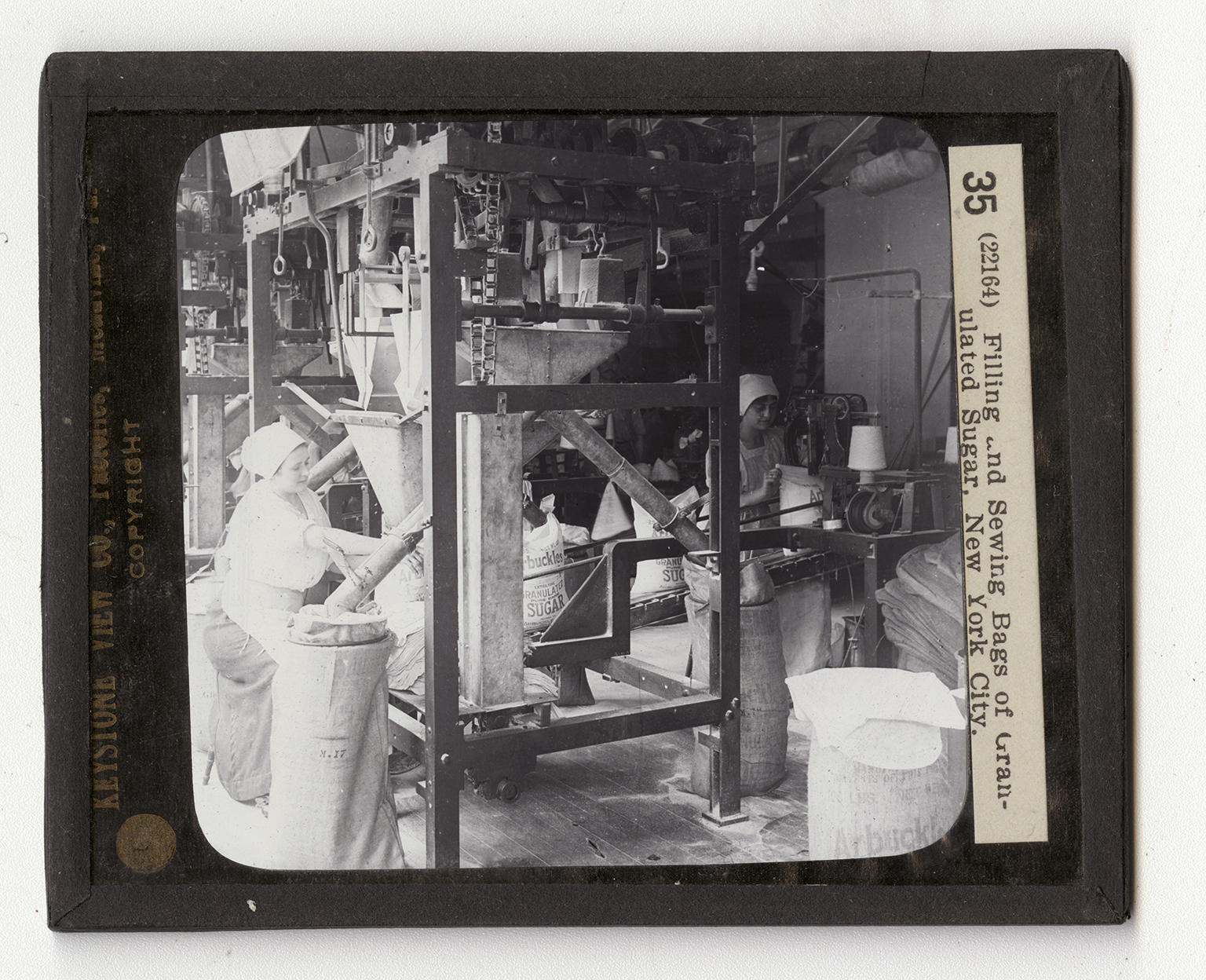

Here you see one of the last processes of sugar refining. The refined sugar comes from the floor above the one shown. It falls into first one and then the other of the two dumps directly above the funnel which empties into the sack. Each one of these dumps is so arranged that it trips when a certain number of pounds of granulated sugar pours into it. Each dumping exactly fills a bag. While the sugar is pouring down into the bag from the one dump, the other is being filled. The bags are set on an endless belt which carries them to the sewing machine in the right of the view. Here the tops are stitched together. They continue on this belt into the packing room. The center of the sugar refining of the world is on the waterfront of Brooklyn. To these refineries are brought shiploads of raw sugar. These ships carry about 10,000 tons each. Raw sugar is a brown, moist sugar, most of which

Card Back:

come from Cuba, Porto Rico, and certain of our southern states. One single refining company has 650 ships that dock annually at their refineries. By refining we mean making from the raw sugar the sugar of high grades of varying degrees of color and crystals. The present method of refining involves between 20 and 30 steps, depending on the nature of the refined product. The first thing is to melt the raw sugar, then to clarify it, then to filter it, and lastly, to crystallize it. Formerly, filtering was done by straining the sirup through blankets. It was then clarified by using clay, albumen, and bullocks' blood. Bone-black is now used to clean the raw sugar, and bag filters take the place of the blankets. Instead of drying the product in ovens, a centrifugal is now used. A rapidly revolving drum throws off the water, leaving the sugar.