Negative Number: 22165

Latitude: 41.0

Longitude: 74.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): Middle Atlantic States: New York

Card Front:

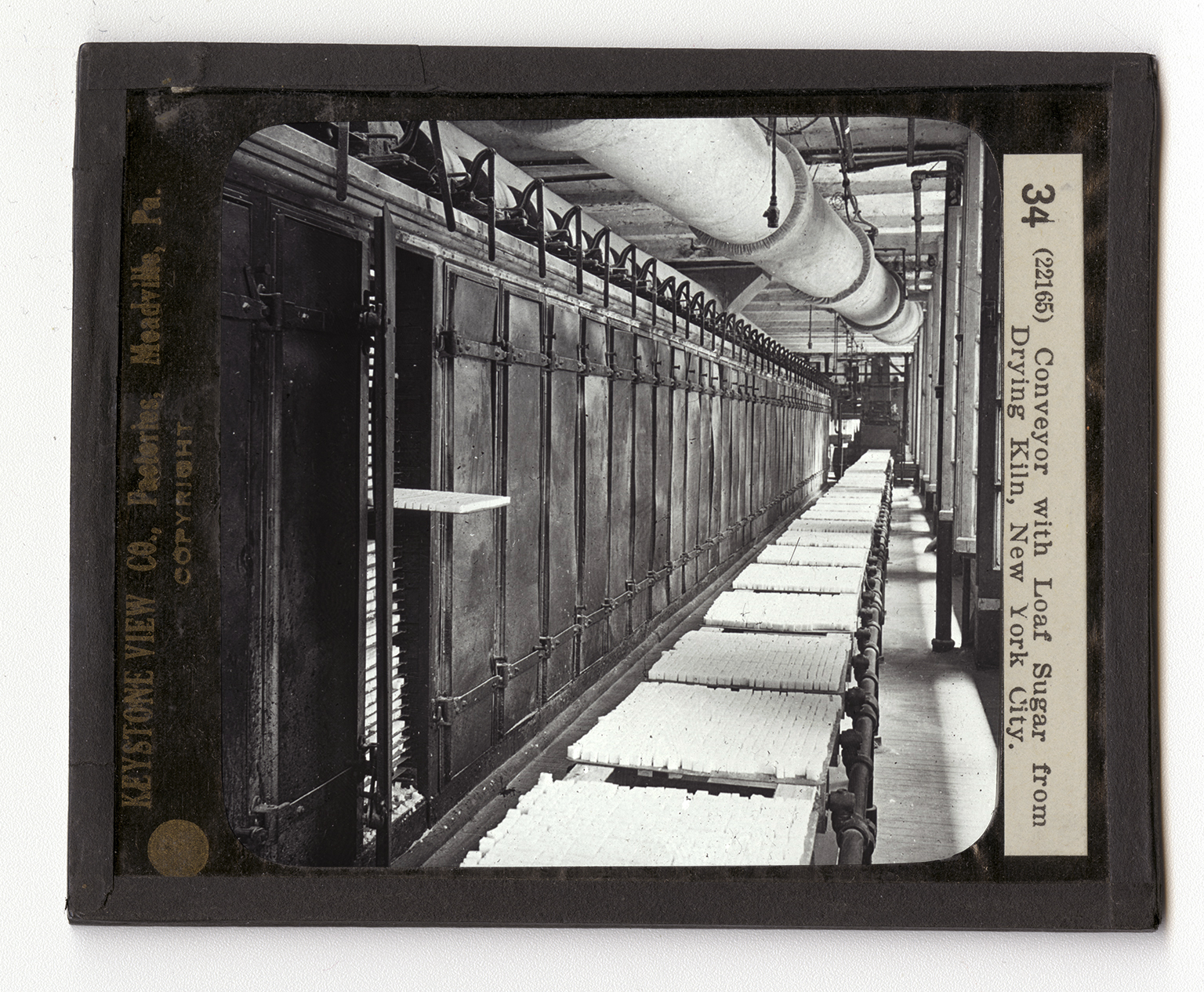

Here is shown the finished product of a modern sugar refinery. Here are trays upon trays, in an endless chain, of loaf sugar, going from the drying kilns to the packing department. There are two general processes to be taken into account in the making of cane sugar. The first has to do with the raw sugar only. This raw sugar is made either on the cane plantations or in cities nearby. The juice is squeezed from the cane stalks and is boiled down into sirup and dried. It is then unrefined "brown" sugar which is sometimes offered for sale. This is the raw sugar which the refineries buy in the open market. The next step, and the one we are now interested in, is changing the raw sugar into the clean, white sugar, the highest form of which is the granulated loaf. After the raw sugar is received at the refinery, it is melted and the sirup is clari-

Card Back:

fied and filtered. This means that the impurities have been removed. The sirup is then put into centrifugals which throw the water particles off as they turn, and leave the little granules of sugar behind. These are then compressed into blocks or loaves, packed into boxes, and put on the market. The largest sugar refining company in the United States produces every year, in sugar and sirup, 80,000 carloads. If you were to place these cars end to end they would reach from New York to Cleveland. This is just about one-third of the sugar the United States uses in a year. To bring in the raw sugar to the refineries of this company, 650 ships are used. To carry their various products, 135,000 cars are annually needed. The same firm uses a great forest every year for the making of its sugar barrels.