Negative Number: 21870

Latitude: 11.0

Longitude: 76.0

Geographical Classification:

South America: Peru

Card Front:

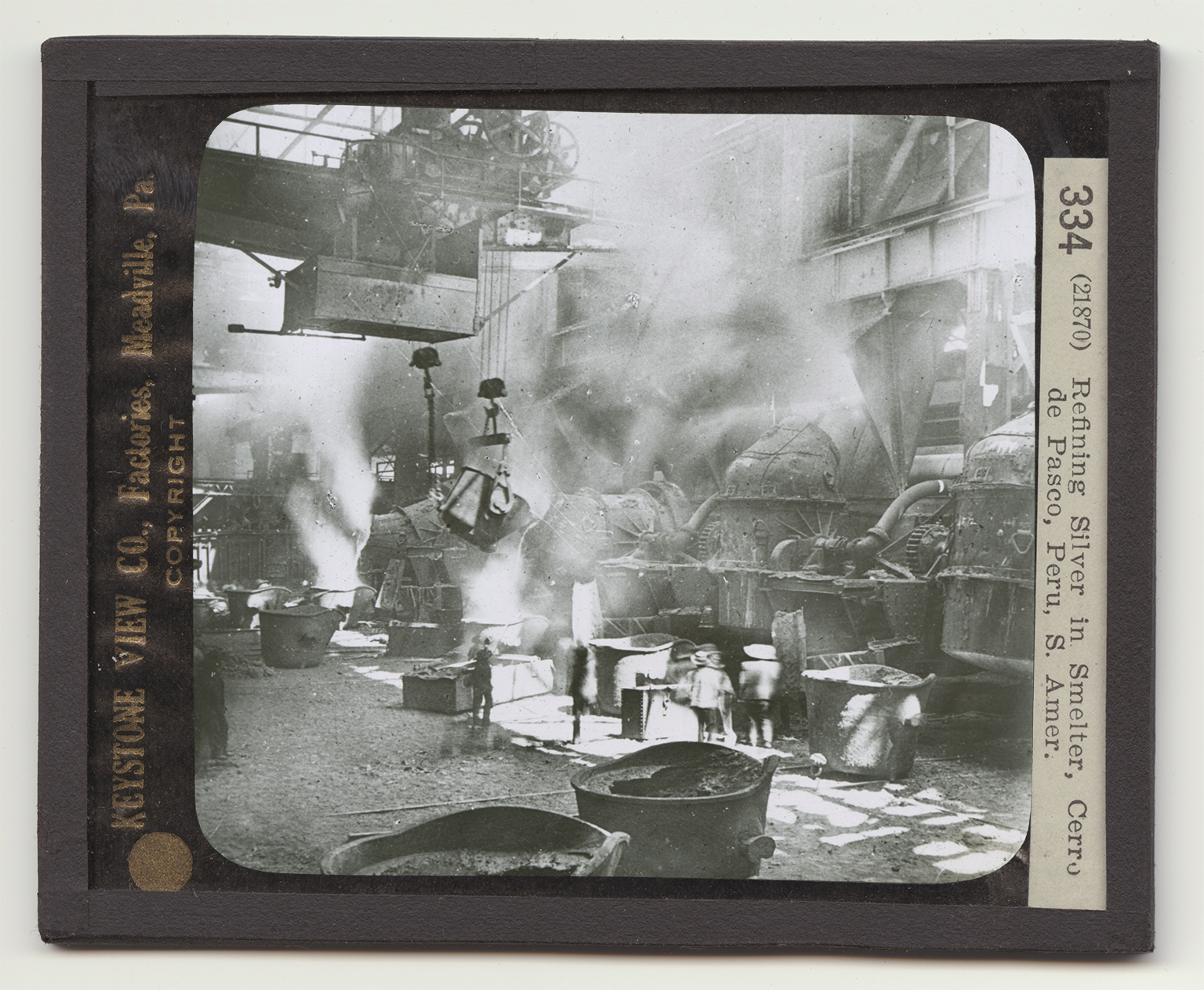

Cerro de Pascois a mining town in the highlands of Peru. It is 14,300 feet above the level of the sea, and is said to be the highest city in the world. All about the city tower the peaks of the Andes, some of which are 20,000 feet high. It has a population of perhaps 15,000, most all of whom are Indians. Cerro de Pasco is in the midst of rich copper and silver mines. The silver smelter which you see here is about six miles form the mines. These mines are owned and operated by Americans. Some 2,000 of the Indians are hired as laborers, with Americans as overseers. Copper is the most important mineral product of Peru, but with it is also mined silver ore. Four-fifths of the Peruvian silver comes from the same mines that produce copper. The processes of refining silver are difficult to understand. As in the refinement of other met-

Card Back:

als, heat is the big factor. Lead ores are used in the smelters to collect the silver, and afterwards these two minerals are separated. Here you see a row of giant retorts, the big furnaces on the right. The metal is being poured into one of these by a giant crane. This crane is moved on the tracks at either end of its heavy steel support so that it readily passes from one retort to the other. The four derrick chains, with the hook attacked are lowered to pick up a ladle of the metal. The crane then lifts this big ladle of the metal. The crane then lifts this big ladle and passes it to the retort that is to be filled. At the same time that the ladle is fastened to the crane, a chain is hooked to a strap at the back of it. When the ladle has been lifted to the proper position, this chain in the rear is pulled up by the machinery so that it drops its conntents into the heater.