Negative Number: 20817

Latitude: 23.0

Longitude: 47.0

Geographical Classification:

South America: Brazil

Card Front:

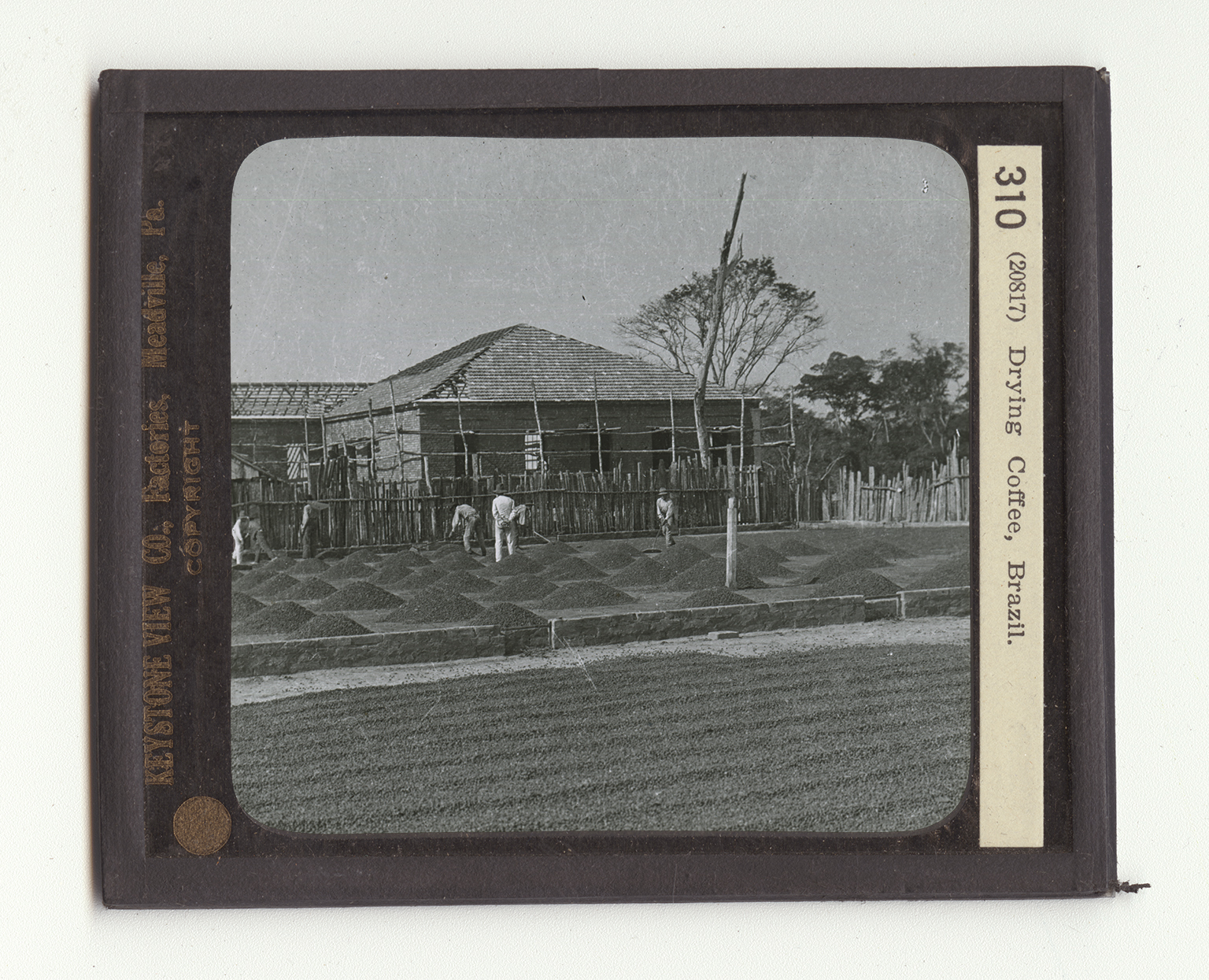

You see here one of the steps in the preparation of coffee for market. This is coffee drying. To understand why this is done, let us recall what coffee is like. Coffee berries grow on trees from 8 to 10 feet high. They are cut back to this height because they grow better berries when trimmed, and also because it is easier to father the berries from a bush than from a tree. In a wild state coffee trees may grow to be 30 feet tall. The berries look like dark red cherries. Inside the pulp is the bean - two half beans with their flat sides together. These are held together by a covering of two layers of skin. After the berries are picked the pulp is mashed off the seeds, and the seeds are washed in vats. The pulp is useless. The seeds are then put out to dry. As you see in the view the drying process is not an easy one. Great cement floors are

Card Back:

built on the ground where the soil is well drained. The green, wet coffee is spread on the floors in the sun. Drying coffee is a fine art. The seeds must be stirred and raked about so they will dry evenly. Then, too, the drying floors must be covered each night to keep out the damp. And if a shower comes up the canvas must be put over the floors at once. Do not confuse the drying with the roasting of coffee. Coffee is shipped dried, but green in the bags. It is roasted usually in the country to which it is sent. On the west side of the lower City of New York there are factories of many coffee importers. Here coffee is roasted, different brands are graded and put in packages or in sakcs. The streets in this section of the city smell of roasting coffee.