Negative Number: 20916

Latitude: 45.0

Longitude: 74.0

Geographical Classification:

North America: Northern Countries of North America: Canada

Card Front:

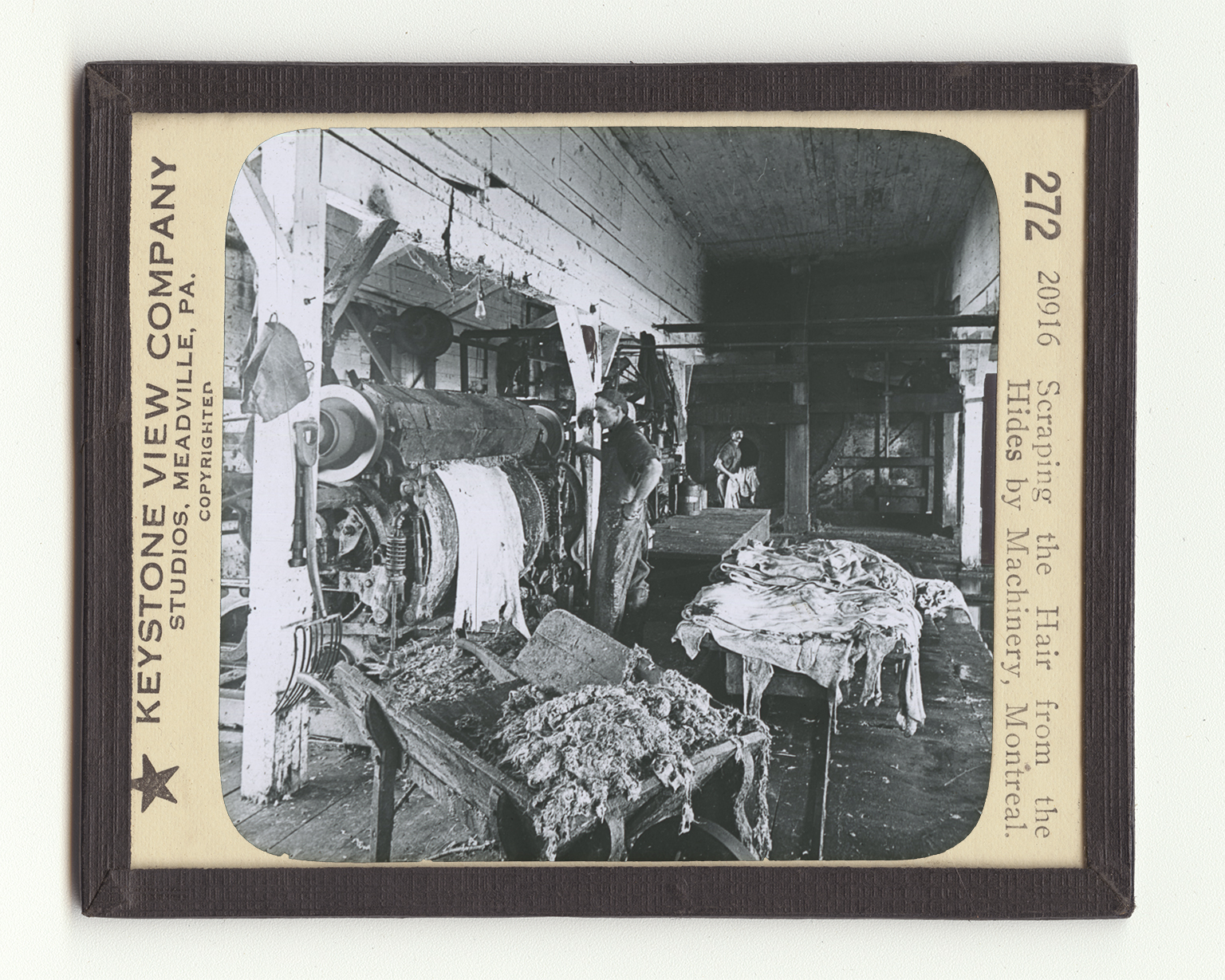

Salted hides are shipped from slaughterhouses to tanning mills to be made into leather. When they reach the mill they are first soaked in vats of water. After they are dried they are put into a large drum, the inside of which contains many pins. As the drum revolves, the hides are softened so that they can be readily worked. You see in the extreme background a portion of one of these drums. From the drums the hides are taken to vaults where they decay in a cold sweat for a couple of weeks. Then they are taken to the unhairing machine. It is this machine that you see in the foreground. The hides are run between two rollers which removes most of the hair. This hair is scooped from the floor, is placed into wheelbarrows, and scattered on the floor of the drying room. It is used later in the making of plaster, matresses, and in upholstery.

Card Back:

From the unhairing room the hides are taken to the beaming room where they are drawn over huge beams, or logs. Here they are scraped with knives so as to remove all the particles of flesh or hair that remain. All these processes are in preparation of tanning. Hides and skins are changed into leather by tanning. The word comes from "tannin", a chemical substance found in the barks of many trees. The bark of the chestnut, elm, pine, and spruce are rich in tannin. The hides are first placed in vats containing a weak solution of this tannin. Here they remain for several days. Then they are placed into vats containing a stronger tannin; and so on into succeeding vats. By the end of 6 or 7 months the hides have been changed into fine leather. In some places chemicals are used in the making of chrome leather.