Negative Number: 20932

Latitude: 45.0

Longitude: 74.0

Geographical Classification:

North America: Northern Countries of North America: Canada

Card Front:

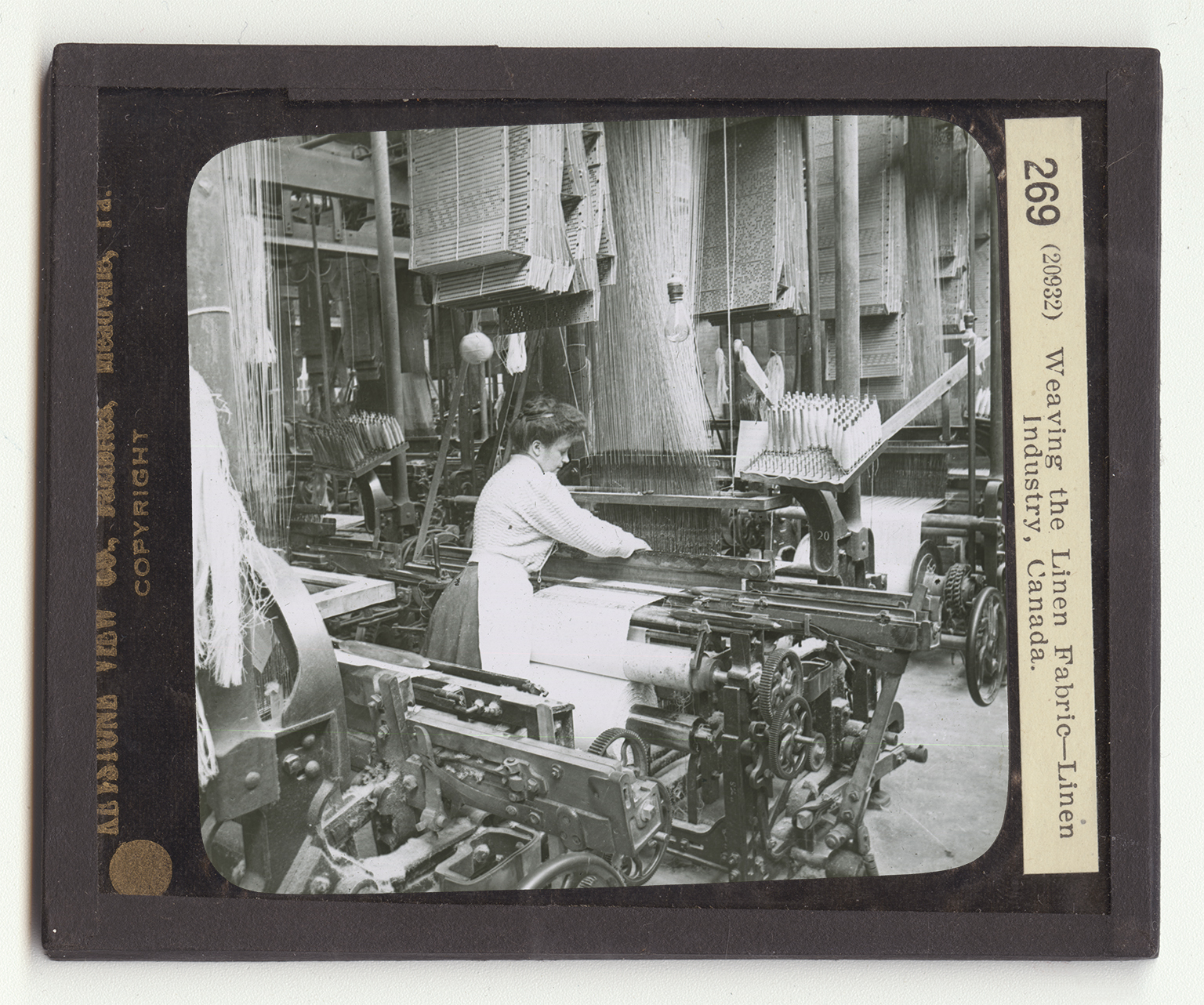

After the bobbins are filled they are sent to the weaving room. You can see a number of looms busy weaving thread into linen cloth. The processes of weaving linen are much the same as those of weaving cotton goods. Our great-grandmothers spun by hand many fine pieces of linen for dress goods, and for great-grandfather's pantaloons. The spinning was done on spinning wheels run by the foot. Cloth was woven on hand looms. The methods of weaving in our large factories to-day are much the same as those our great-grandmothers used. One set of linen fibers runs to the loom lengthwise. This is called the warp. It is the threads of the warp that you see coming down from the floor above. Each of these threads passes through an eye fastened to a pair of heddles. Each thread then runs between fine wires, set in a narrow, oblong frame. These wires are called

Card Back:

reeds. The eyes and the reeds prevent the threads of the warp from becoming tangled. Linen is made as other cloths are made, by shooting the threads of woof cross-wise through the threads of the warp. As one of the heddles lifts its set of threads, the shuttle bearing the threads of the woof travels across between the layers. Then the first heddle drops, and the second rises. The threads of the woof are again shot across. In this way, the fabric is woven very smoothly and very rapidly. There are some linen factories in the United States and in Canada, but the greatest of these are in Europe. Throughout, the Netherlands, France, Austria, Great Britain, and Ireland are large linen mills. The linens of Belgium are especially fine. Here are made laces and handkerchiefs. France excels in cambrics and lawns.