Negative Number: 20316

Latitude: 42.0

Longitude: 73.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): New England States: Connecticut

Card Front:

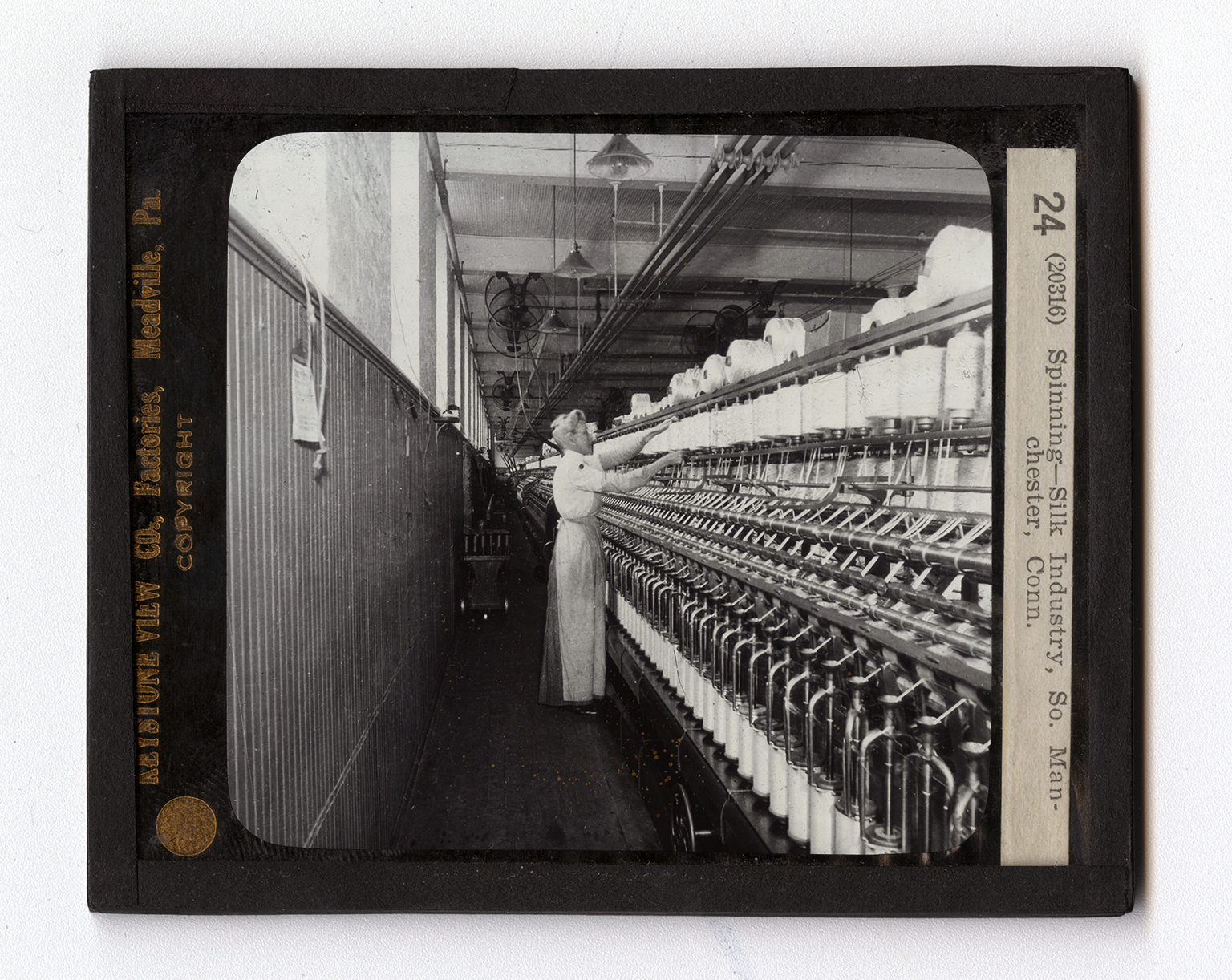

This is a long spinning frame in a silk mill. The bobbins at the top of the frame hold the silk which is known as "roving". This "roving" is the silk that has been cleaned, combed, and straightened so that its fibers are welding together. At the bottom of the frame you see the spindles that contain the thread. The "roving" passes down over the machine in such a way that the fibers are twisted into threads by these spindles. These threads are called "singles". The "singles" are next cleaned in a wonderful way. They are run rapidly over a gas flame which burns off the fuzz. The process requires an unusual amount of care. Should the speed of the machines which draw the threads be slackened the least bit, the threads are liable to catch fire, or be weakened by the scorching. The threads then pass through a machine called a controller, which removes the knots and

Card Back:

which makes the threads the same size. They are then reeled into skeins, inspected, and sent to the warehouse. Here they may be dyed or sent to the mill to be woven into plain silk goods. It should be remembered that the silk so spun is quite different from reeled silk. In the reeled silk, the "singles" go to what is called the throwing mills where it is twisted, doubled, and twisted again so that the right sized thread is formed. These threads are reeled into skeins and then put upon bobbins. In the big mills here shown there are almost 40,000 spindles used in "throwing", winding, and spooling the silk. The extent of the silk industry is measured by the number of spindles in the factories. The census of 1910 shows that there were 2,400,000 spindles in the United States. This number has probably been increased to 3,000,000.