Negative Number: 20301

Latitude: 42.0

Longitude: 73.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): New England States: Connecticut

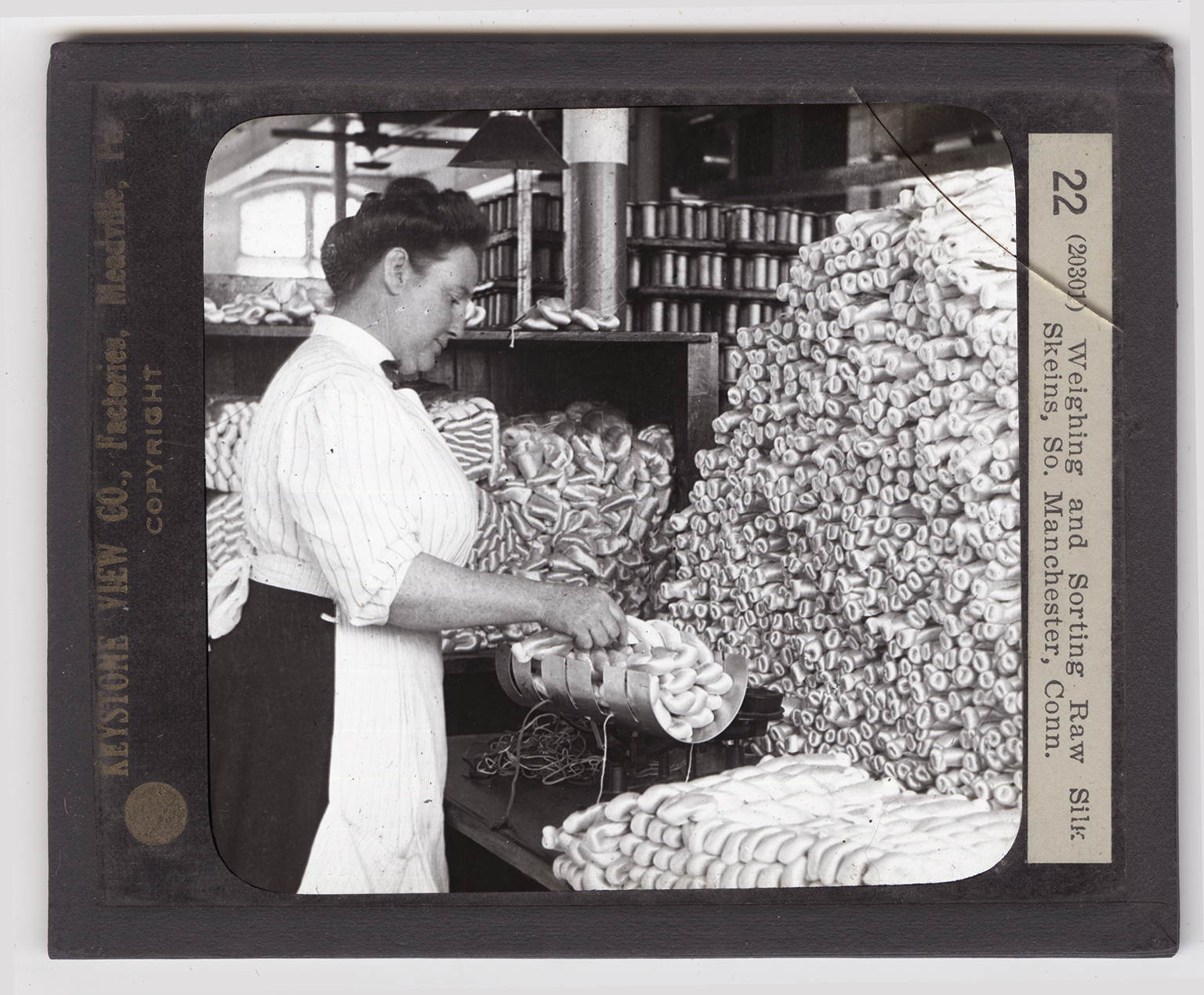

Card Front:

This shows one of the first processes in the manufacture of silk in the United States. This is the room in the factory in which the bales of raw silk are opened. All of our raw silk comes to us from abroad. By far the most of this comes from eastern and southeastern Asia, particularly from the countries of Japan and China. In these countries the silkworms are grown and do their weaving. The threads of the cocoons which they weave are unwound and spun into tiny threads of yarn. These threads are made up into skeins such as you see in the view. This is known as raw, or reeled silk, as against manufactured silk; that is, silk made up into goods. Before the raw silk leaves Japan, for example, it is carefully weighed and graded. Raw silk absorbs a great deal of moisture, and this must be taken into account in the weighing. The skeins are re-reeled to find out the number of broken

Card Back:

threads. Naturally, the more broken threads, the less valuable the silk is. The first thing to be done in the American factory is to check up these weights and gradings. It is this that the woman is doing. On her testing depends the price that the manufacturer pays to the importer. We import far more silk into this country than is brought into any other. In 1913, the United States used as much raw silk as England, France, Germany, and Italy together. The total consumption amounted to 235,400,000 pounds. To make one of these pounds of raw silk, from 2,500 to 3,000 cocoons have to be used. The thread or filament in each pound is about 6,000 yards long. Separate these threads into single strands, and the strands of one pound of raw silk amounts to almost 1,000 miles.