Negative Number: 22127

Latitude: 43.0

Longitude: 71.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): New England States: Massachusetts

Card Front:

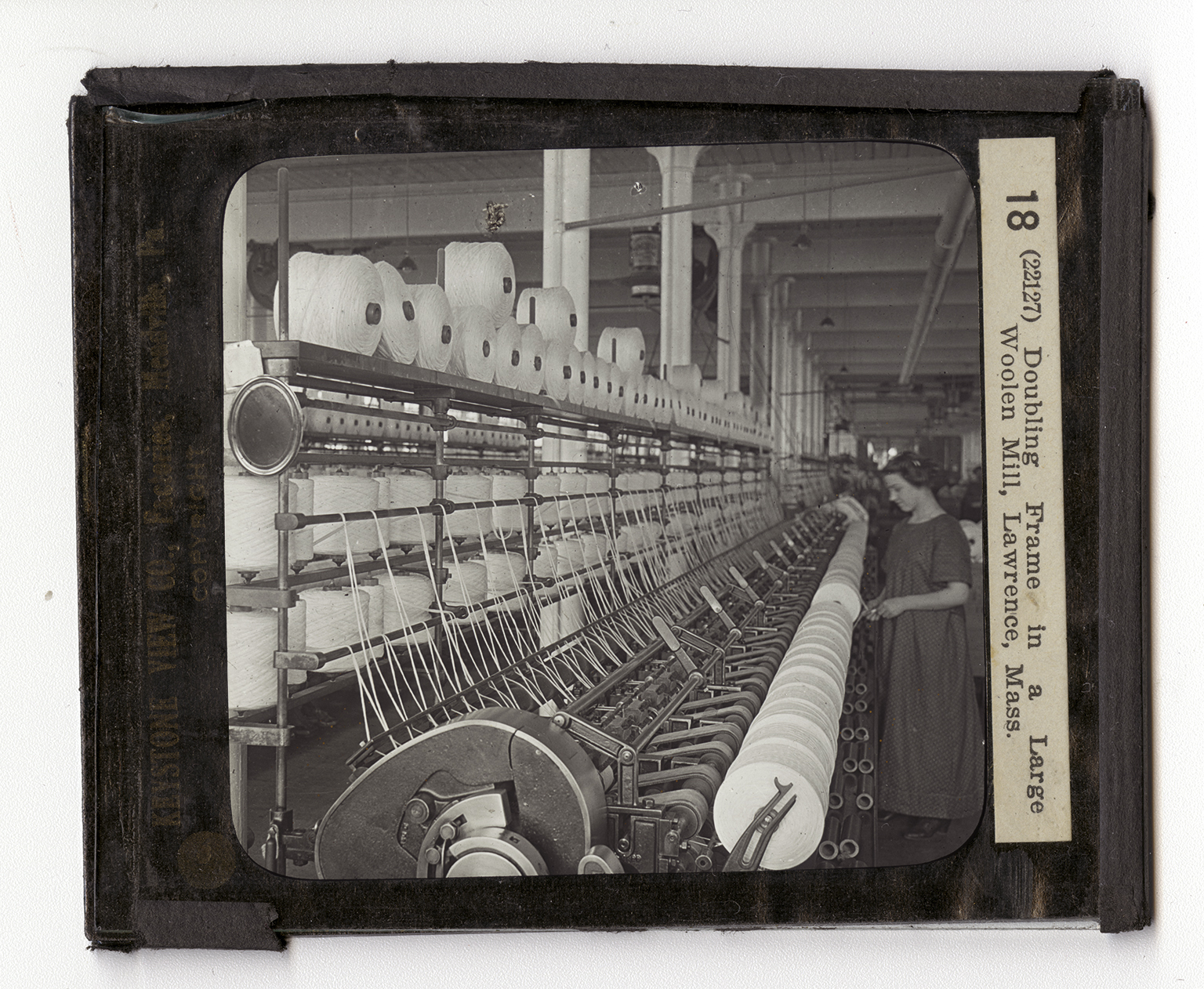

Wool is first graded, then washed in soft, soapy water, run through wringers, and dried. The water must not be hard, since the lime in hard water would fasten the fibers together. Wool must come from the drying rooms light and fleecy. To make it pliable it is sprinkled with oil. Task number two is to straighten these fibers. This is done in carding machines that comb the fibers out flat in a wide sheet. The tips of the fibers are made to overlap at the same time. The sheet is next ripped into strips which run through rolls. These rolls twist the fibers into loose tubes. The tubes are spun into threads which are drawn to the right size. The product is the yarn used in weaving. But it is often necessary to make these yarns two-fold or three-fold. Such yarns are used to make fancy curls, locks, or twists. The machine in which this is done is called a doubling frame.

Card Back:

This name describes its use. You will observe that the threads from the left hand side come from pairs of spools. Each pair of threads goes through the same guard or eyelet. The machine twists these together, or doubles them. Weaving the cloth is the next act. Large looms beat closely together two sets of woolen yarns that run in opposite directions. Finishing woolen cloth is more difficult by far than finishing cotton goods. There are rough spots and knots to be smoothed out, and small holes to darn. Then, too, some of the goods must be highly finished with a beautiful gloss. Because of its softness, the woolen cloth is not easily patterned. Calicoes take prints easily. Woolen goods are soberer in color as a general rule. But when colors are properly combined in woolen goods, the effect is rich.