Negative Number: 22125

Latitude: 43.0

Longitude: 71.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): New England States: Massachusetts

Card Front:

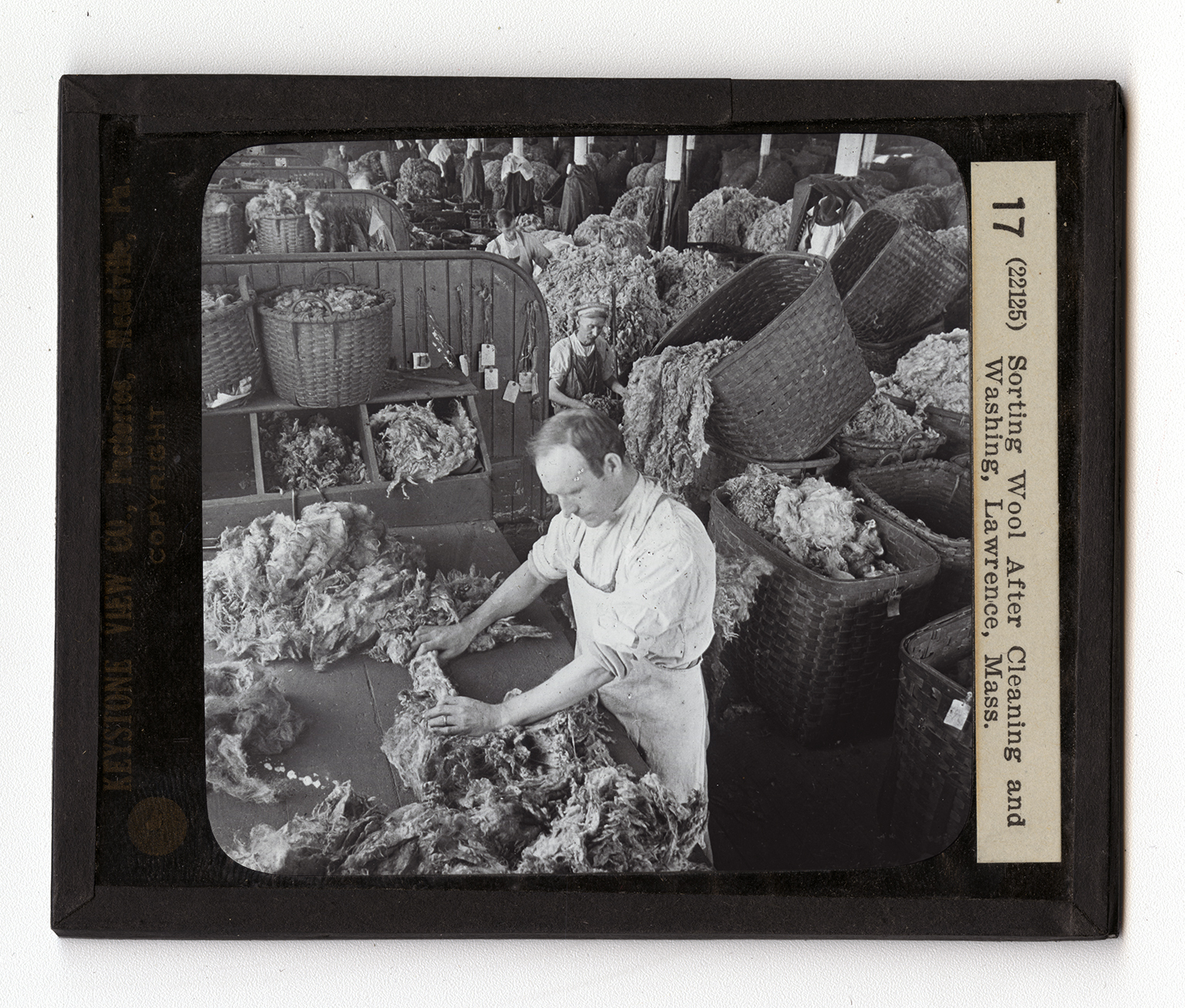

In pioneer days Grandfather sheared the sheep, and Grandmother sorted the wool and carded it. She then spun her yarn from these on a little spinning wheel that twisted the strands of wool in a smooth long cord. These threads she dyed, and then took great skeins of them to the weaving room. One set of threads she placed lengthwise in the big loom, putting them close together, till she had her strip of "cloth" the width she desired. Then she began weaving by running other threads across and over the lengthwise ones. Both sets were beaten tightly together as she went. Thus she made a strip of strong woolen cloth. There is really no difference between processes of cloth making as Grandmother knew them, and those of the present day. In our great factories hundreds of spinning machines fill the bobbins rapidly. Hundreds of looms take the

Card Back:

threads so made and weave them into cloth. The work is done faster and evener than Grandma could ever have dreamed of. But the foreman of the factory would tell you that Grandma knew the chief tricks of his trade. Here for example is the same old process of wool sorting that Grandfather knew something about. The first task is to divide each fleece down the back. The wool from the back and sides of the fleece is put in Grade A basket. Grade B is from the lower parts of the fleece. Grade C is the "rag tag" from the legs; and so on. The man in this picture is busy grading wool. His senses of sight and touch are keenly alive to the values of every part of a fleece. On his judgement depends the final quality of every piece of woolen goods made from the material he grades.