Negative Number: 22044

Latitude: 47.0

Longitude: 88.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): North Central States: Michigan

Card Front:

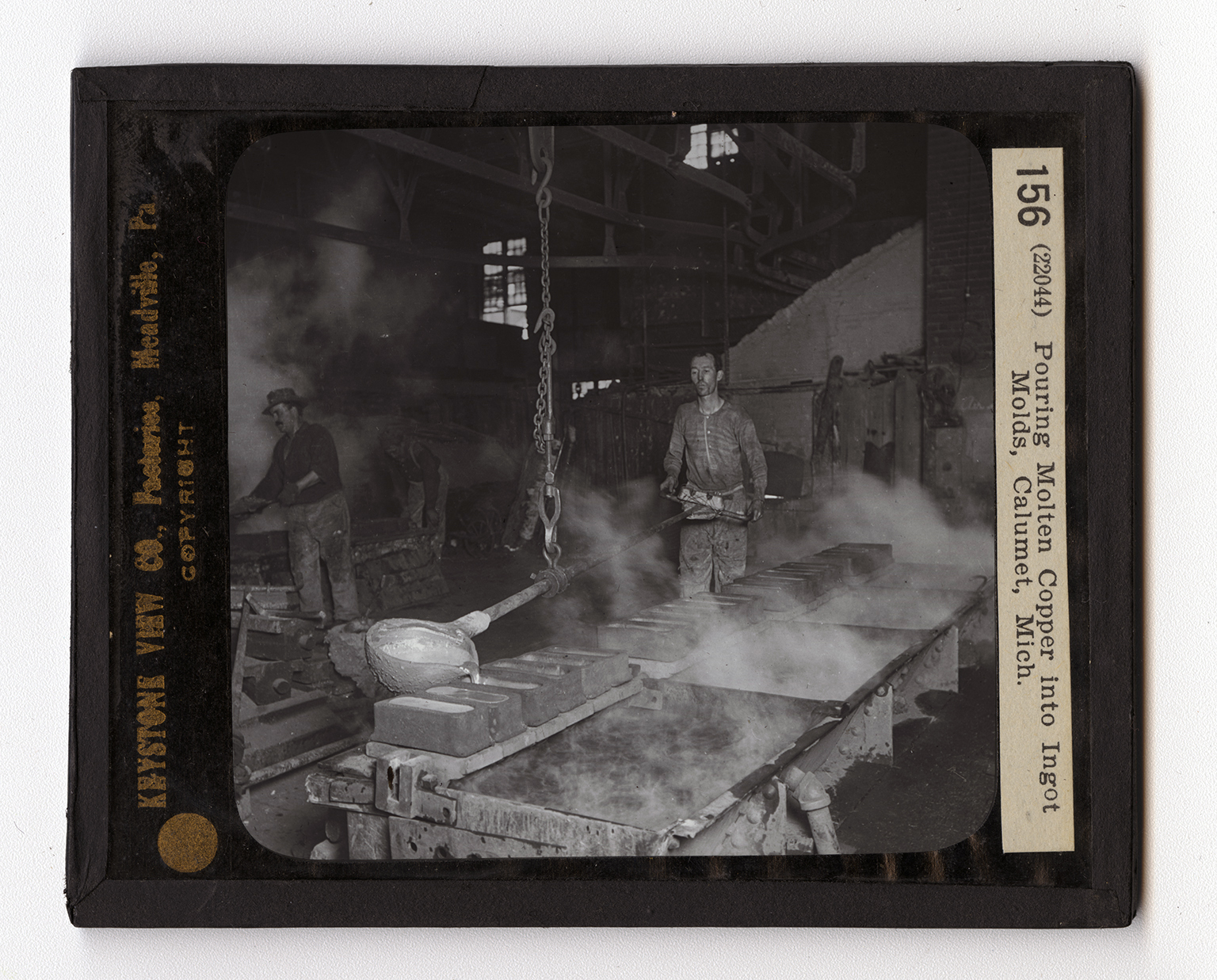

Copper-bearing rock is blasted free from the lode, or mother vein, and then dumped into tram cars. These tram cars hold as much as 2 1/2 tons of the rock. They are run on tracks to the elevator shaft and the mineral is raised to the surface. It is dumped into "skips" which old 7 1/2 tons. From the skips the copper rock goes to the rock house to be crushed. Then it is loaded into 40-ton cars for shipment to stamp mills. At the stamp mills the rocks are crushed, concentrated, and washed, and the product goes to a smelter, such as is shown here. Heat is the great factor in reducing the pure copper from the stamped rock. The molten metal is dipped from the furnaces and poured into little molds. Observe the manner in which the dipper is operated. A chain is fastened to a sliding pulley which runs on a steel beam. This arrangement permits of the free movement of the ladle. The

Card Back:

long hande allows the man to work at some distance from the hot metal. These processes of working copper on a large scale have been developed recently. Our demands for copper have increased a thousand fold in the last few years. This is largely due to the calls made by electrical appliances. Copper is the best conducter of electric current known. Every time you talk on the telephone or ride in an automobile or street car, you do so because of the work of the men in the copper mines. There are annually produced in the world over 2,000,000,000 pounds of copper. The United States furnished 56% of this. Michigan was formerly our greatest copper-producing state. Arizona now leads, with 33% of our copper. Montana is second, with 23%; Michigan is third, with 13%.