Negative Number: 22082

Latitude: 43.0

Longitude: 71.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): New England States: Massachusetts

Card Front:

After the cotton fibers are twisted into threads called yarn, this yarn is put into great looms and woven into cloth. The process of weaving consists in criss-crossing in regular fashion, two layers of threads running in opposite directions. After the cloth is woven there is still much to do before it is marketable. From this point on, the various processes are referred to as finishing and printing. When the clothe comes from the looms it is a brownish gray. It must be singed to make it smooth and then bleached to make it pure white. It is singed and bleached in strips. In the mills here pictured, pieces of gray cloth are sewn together till they make a strip about 40,000 yards long. That is, 23 miles of cloth move over gas flames which burn off the fuzz. This is a delicate process, for if the flame is a bit too high, or the speed of the cloth too slow, the strip will catch fire. The strip

Card Back:

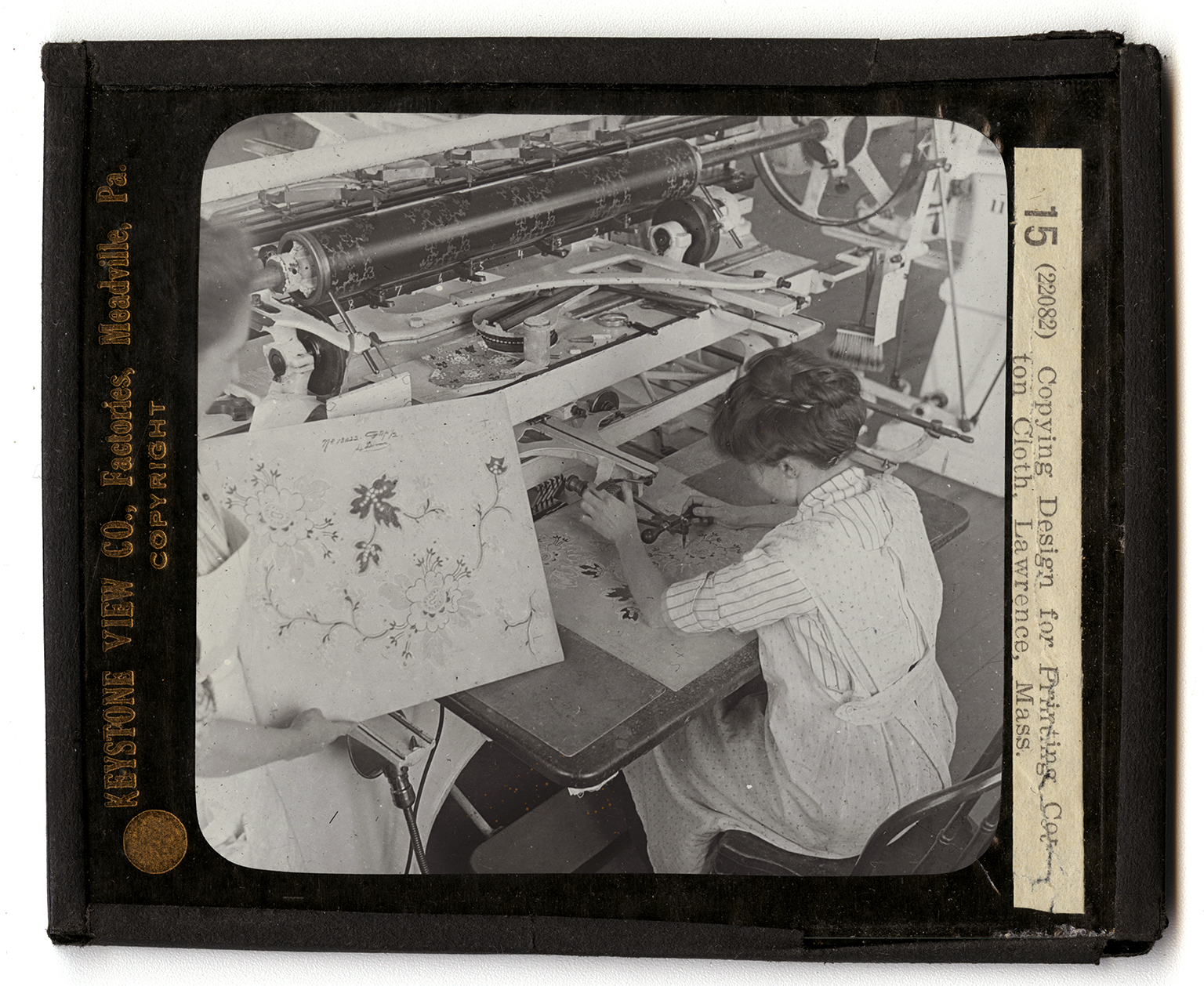

of cloth next passes into bleaching vats where it is boiled in chemicals which make it pure white. This cloth is now ready for market as white cloth. But much of the demand is for colored or patterned goods. The patterns are printing on the white cloth by copper rolls, much after the fashion of paper printing on roller presses. To get the design on the rolls is the next step. This is the making and the transferring of the design. Skilled artists draft suitable designs. These are photographed, engraved on zinc, and transferred to the copper rollers by a chemical process. Each color demands a separate plate. The girl in the view is busy painting on the engraved zinc plate, those parts of the pattern which belong to one color. Making ready the copper rolls for printing is one of the most interesting processes of cloth manufacture.