Negative Number: 22001

Latitude: 42.0

Longitude: 84.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): North Central States: Ohio

Card Front:

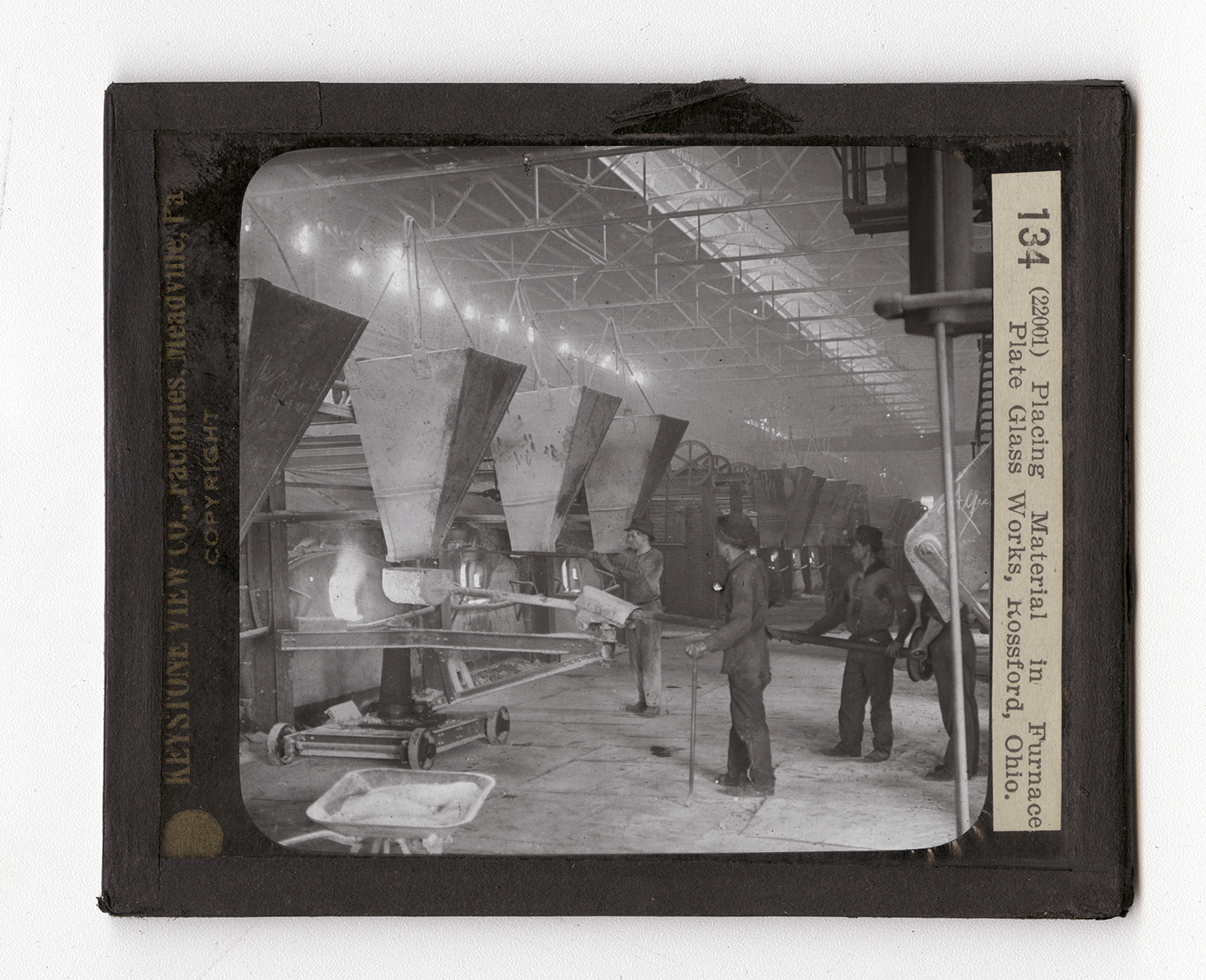

Plate glass is made of pure sand, carbonate of lime, sulphate of soda, and carbon in the form of coke or coal. These materials must first be melted in pots or closed furnaces. The view here shows the method of filling the furnace from the conveyors. You will observe that the great dipper used has a long handle, so that the men may stand away from the flames. The heat from the open furnace is intense. The dipper is attached to a small truck so that it can be pulled along from pail to pail. These pails are also suspended and fastened to a steel overhead truck directly above the furnace. As soon as the dipper is full it is pushed far back into the furnace and the material is dumped out by turning the dipper over. After the sand and other materials are melted and are changed into a pasty substance, this paste is poured on a cast-iron rolled table. The table is mounted on truck which runs on rails so that

Card Back:

it can be shifted from point to point in the factory. Here, on these great, smooth, sheet-iron tables, a heavy roller passes over the paste. This smooths the substance out just as your mother rolls pie dough. These rollers weigh as much as five tons. Just ahead of the big roller, and on either side of it, run two iron guards which keep the pasty glass from spreading out too widely. The third process is that of annealing or cooling the glass. The sheet of plate glass remains on the iron table where it has been rolled until it stiffens a bit. Then, with two or three other sheets, it is lifted by a crane into a fire-brick kiln. Here it rests on a floor of hot bricks. The kiln opening are built up, and the glass is cooled gradually for 3 or 4 days. This gradual cooling prevents cracking, and makes the glass tough. Explain briefly how plate glass is made.