Negative Number: 22060

Latitude: 41.0

Longitude: 82.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): North Central States: Ohio

Card Front:

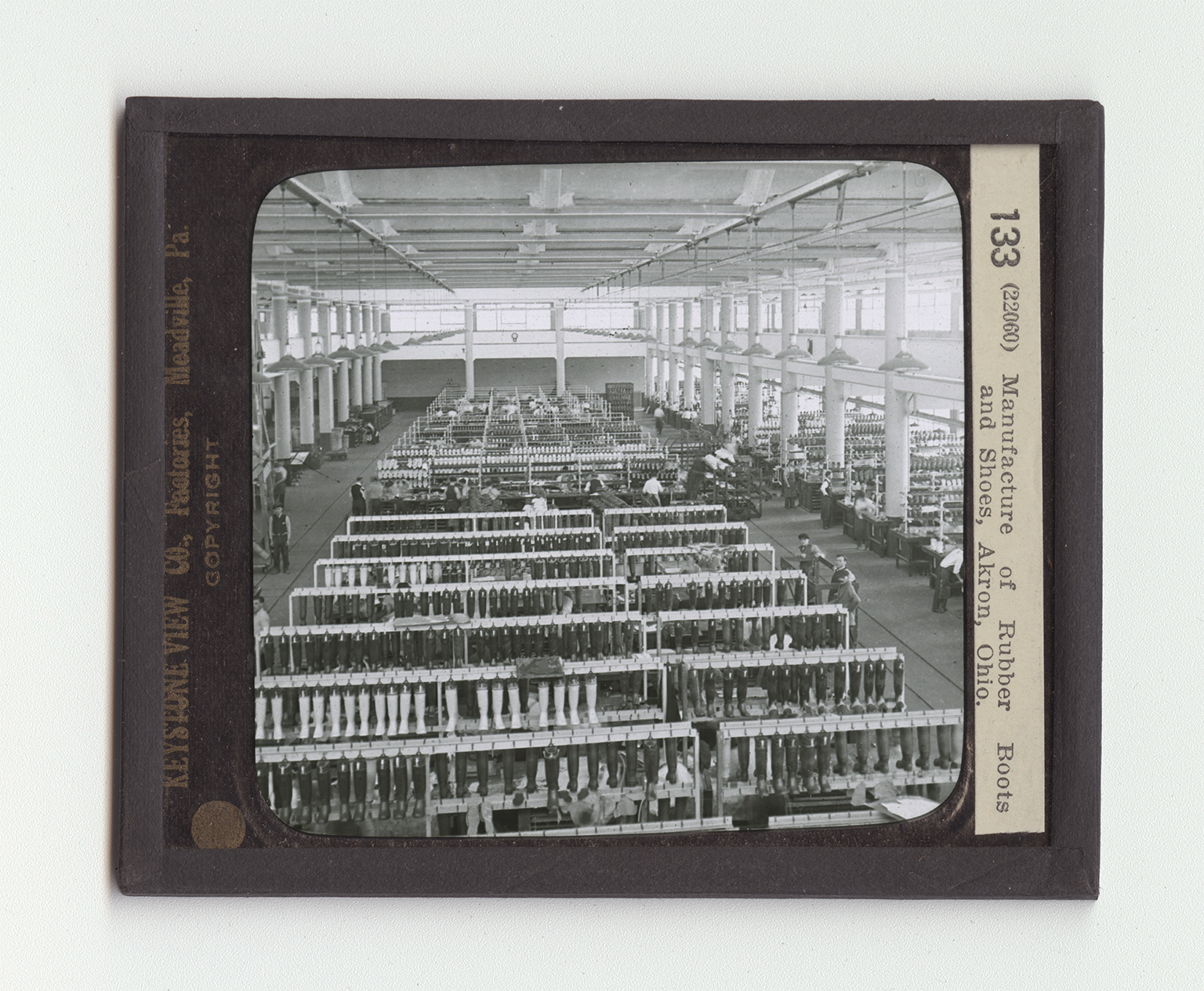

In rainy weather nothing is much needed as a raincoat and a pair of rubber boots or overshoes. In the rubber factory you see here many kinds of rubber goods are made. Raincoats are made by the thousands. Instead of cutting each coat separately, 40 or 50 pieces of fabric are cut out one time by machinery. Each coat so cut follows the pattern to a nicety. Then there is the boot and shoe department. This firm makes about 25,000 pairs of boots and 25,000 pairs of “rubbers” every working day. This means that here 25,000 people could be fitted out dry shod every single day. The section shown here is the boot and “rubber” department. Boots and “rubbers” are built up on a boot or shoe form or last. Pieces of fabric and rubber cut to the proper shape, are laid on the form. The boot or “rubber” is then vulcanized. That

Card Back:

is, it is heated, and the rubber particles are welded together by compressed air. This makes the boot tougher than it could possibly be if built up and merely dried out in ovens. Observe the lighting; the high ceiling; the cleanliness. Men working here ought to be able to keep healthy on account of the good lighting and ventilation. This is a good illustration of our large modern factories. This concern employs in its various departments between 18,000 and 20,000 people. Such factories make a city famous for their product. Look at your “rubbers” to see where they were made. Take apart a piece of a worn-out rubber boot. Notice the way the rubber is driven into the fabric. Where does crude rubber come from? Tell how it is obtained.