Negative Number: 13747

Latitude: 32.0

Longitude: 81.0

Geographical Classification:

North America: United States and Possessions (Except Asiatic Possessions): South Atlantic States: Georgia

Card Front:

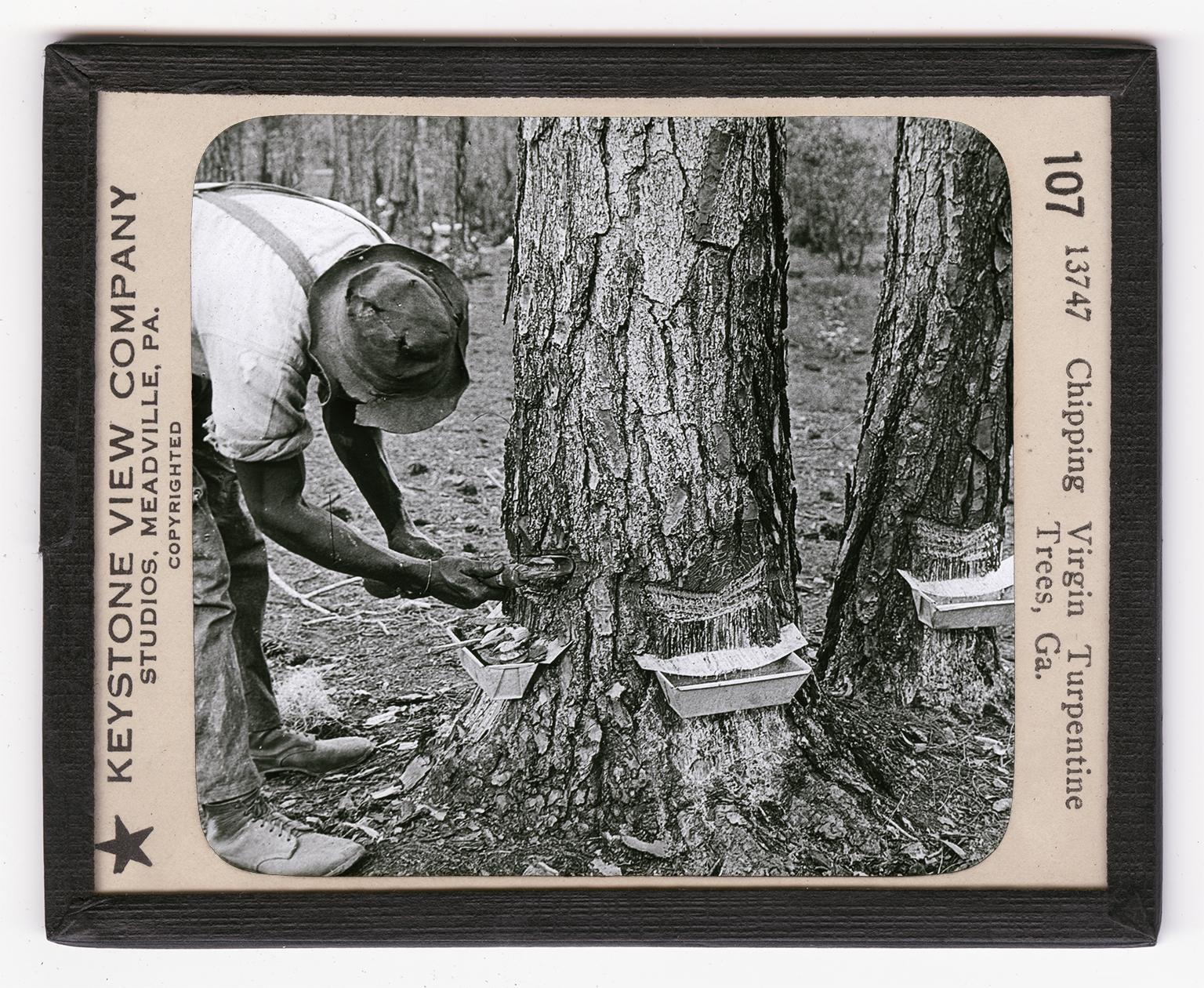

Turpentine, tar, pitch, and rosin are made from sap of the longleaf pine. This tree grows along the Atlantic Coast from North Carolina to Florida. You can see here how the sap of the tree is obtained. A notch, called a box, is cut at the foot of the tree. Above this box the bark is scarred or gashed so that the sap, in the spring, oozes out and runs into the box. The man at the right is chopping the bark. The man at the left is dipping the turpentine from the box into a keg. When the kegs at the various trees are full, they are gathered up and taken to a distillery. At the distillery the sap is boiled and the turpentine, in the form of vapor, rises into pipes. These pipes are cooled by spring water. This cooling condenses the turpentine, which then runs into barrels. The barrels are sealed and hauled to a shipping point.

Card Back:

The United States leads all other countries in the production of turpentine, rosin, and tar. Nine-tenths of these so-called "naval stores" come from the turpentine farms in our Southeastern Atlantic States. North Carolina formerly led in their production. But the trees of this state have been pretty well used up, so that Georgia and Florida now lead. Savannah is the chief port of shipment for naval stores. A turpentine farm contains thousands of trees. These trees, as you see, are not large, but they are tall and very straight. They are scarred from the box up to the height of a man's head. The size of a farm is reckoned by the number of boxes producing turpentine. Some farms have millions of boxes and employ small armies of negroes, who work in gangs under an overseer.